Technology

C3Nano Silver Nanowire Technology Platform Helps Launch Innovations

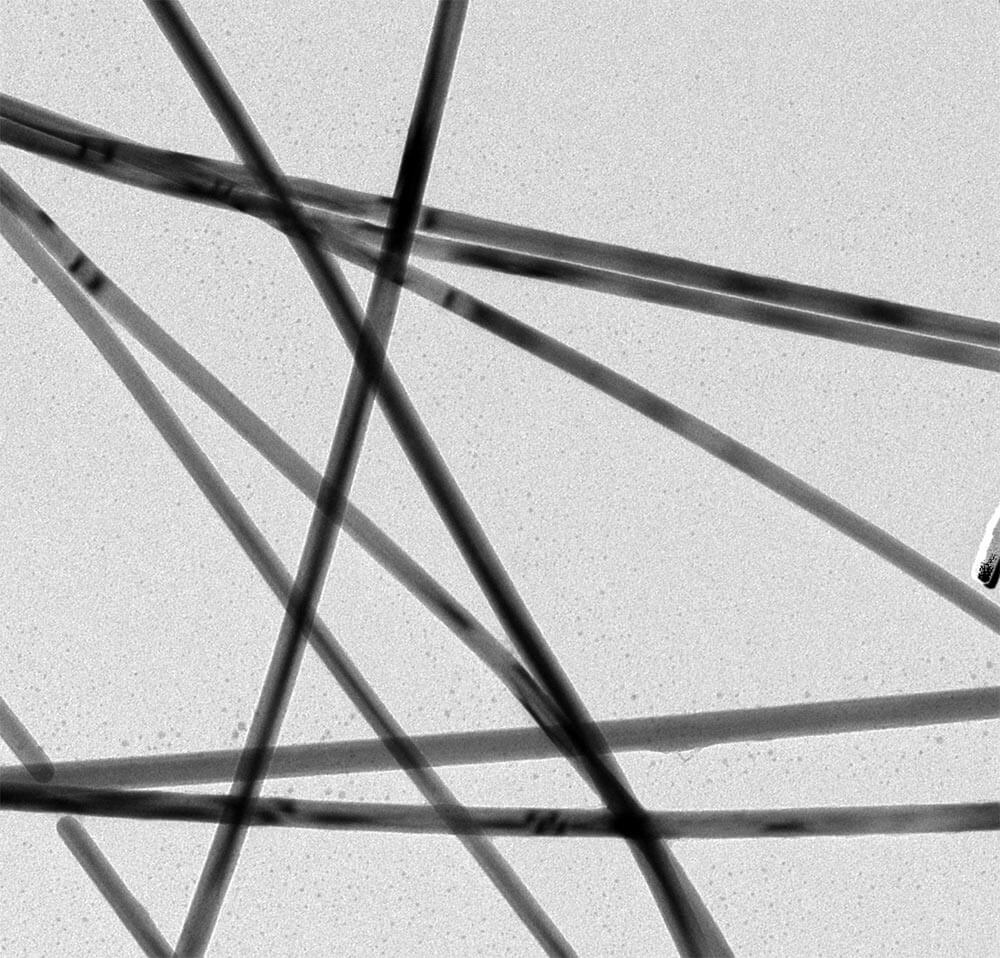

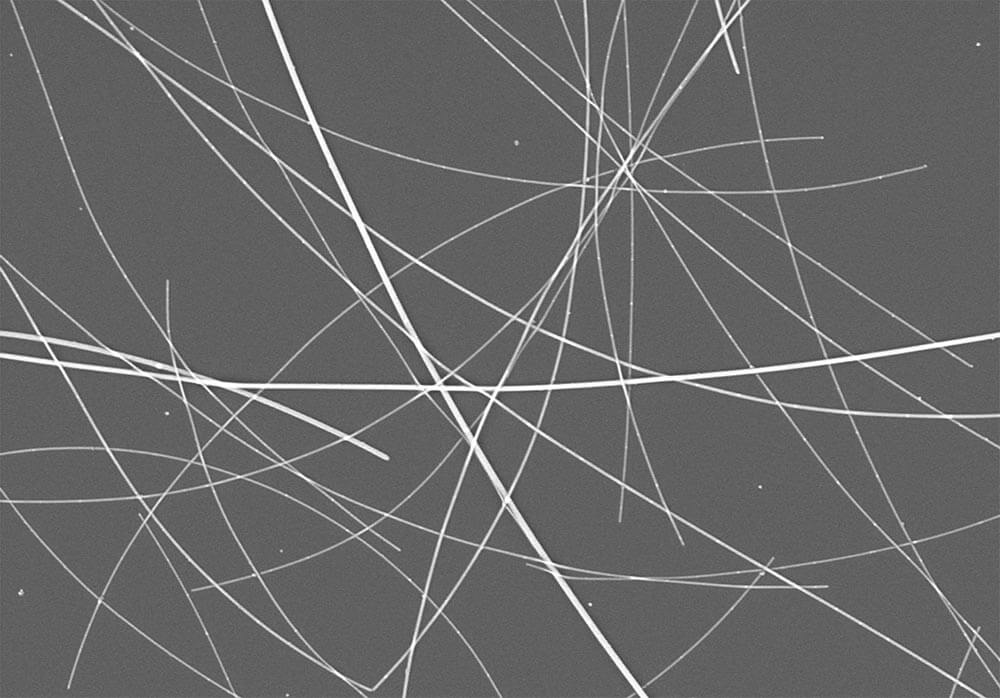

At the core of C3Nano’s comprehensive platform lies our cutting-edge silver nanowire technology, driving technological breakthroughs across a myriad of industries. Our team of dedicated scientists and engineers, empower our customers through every stage of development, from initial ideation and prototyping to seamless scale-up.